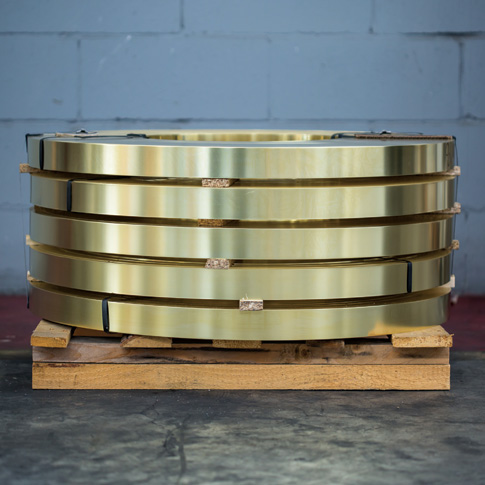

For Cobral, the phase of cutting brass strips is one of the moments in which to pay more attention to quality

Extreme care is placed at the scrawling limits and on the edges of the strips, which must exhibit the complete absence of burrs. Another feature of the semi-finished brass is the finish on the surface: the company guarantees a grain of porosity and the supply of glossy mirror material.

The minimum width of brass strips is 8 mm. You can make a finished product according to the specifications, supported by a guarantee and technical support.

Coding the Specification

In the first phase of the Cobral project, samples of brass strips can be produced to determine the machining specifications. This service guarantees a finished quality product that meets the fulfillment of technical requirements and agreed lead-time in the order phase.

Attention to the quality

Carefully checked bowing, completely burrs-free edges, mirror gloss and porous grain make Cobral brass strips of high quality products.